Difference between solo, tandem and synchro operation

The "normal case": window or skylight dome and a drive. But what to do if the skylight dome is very large or the conservatory wing is very heavy?

With upward opening elements (skylight dome, conservatory wing, ...) the weight plays a role on the one hand, but also the size. Imagine you have a skylight dome with 2m edge length and only one drive. It may be strong enough to lift the dome. When the skylight dome is open, there is 1m space left and right of the push rod to the corner. Even a light wind can cause the top part of the skylight dome to swing.

If the windows installed in the façade are very wide, a drive in the middle will not be sufficient to keep the window completely closed in strong winds. The corners will probably no longer sit properly in the frame and the wind permeability will increase (it "pulls").

In our recommendations (for example in our sales consultants) we take this into account and pass on the manufacturer's recommendations, if any. Example: If the window sash is wider than 1.2m, two drives are installed.

Two individual drives vs. tandem operation vs. synchronous operation

Two solo drives

If two individual (solo) drives are connected in parallel, each drive runs quasi "on its own". If one should fail (defect, load disconnection), the other will continue to work. In the worst case, this can lead to the sash / skylight dome top part breaking.

It must also be taken into account that two drives never run at exactly the same speed due to production reasons. Tolerances of up to +-10% can occur here. If no glass element is installed, this is usually irrelevant. During opening or closing, the sash or the top part of the skylight dome is slightly inclined, but when it reaches the end point, one drive catches up with the other and everything is straight again.

Advantage: Favorable, because no special control is necessary.

Tandem operation

If two drives are running in tandem mode, this means that one drive knows the state of the other. However, this only applies to "drives or does not drive". So if one drive fails, the other one stops automatically. This at least ensures that no major damage occurs to the sash.

Important: However, each drive runs at its own speed (see above).

Advantage: Good interim solution, as slight twisting during travel is usually not a problem.

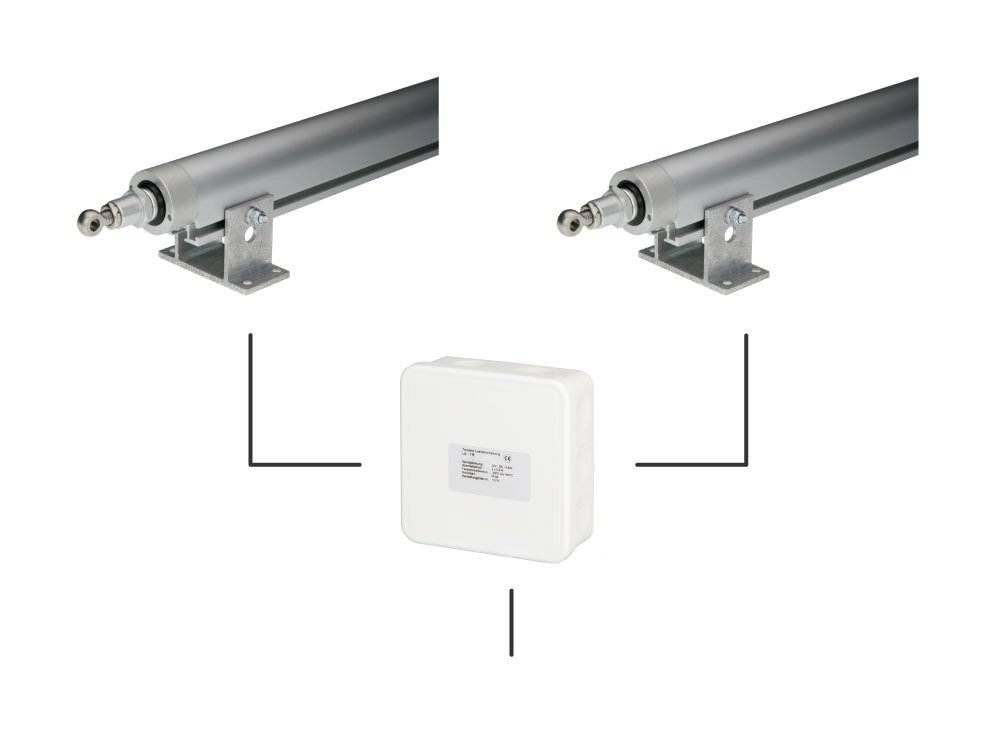

Synchro operation

The drives are electrically coupled via integrated or external electronics. This ensures that the drives run at exactly the same speed. Complex processes are used here, sometimes pulse generators are installed in the drive, the controller "counts" the pulses of each drive per time unit and regulates the voltage for each drive individually. The accuracy is remarkable, acting as if mechanically coupled.

It goes without saying that if one drive fails, the other will also stop.

This method is used in particular when glass elements have to be installed or twisting of the moving part has to be avoided.

Drives for synchronous operation are always in 24V/DC version and require a ventilation power supply if they are to be operated at 230V.

Advantage: Several drives (even more than two possible) have exactly the same speed and work like a single drive. There is no possibility of the sash twisting.