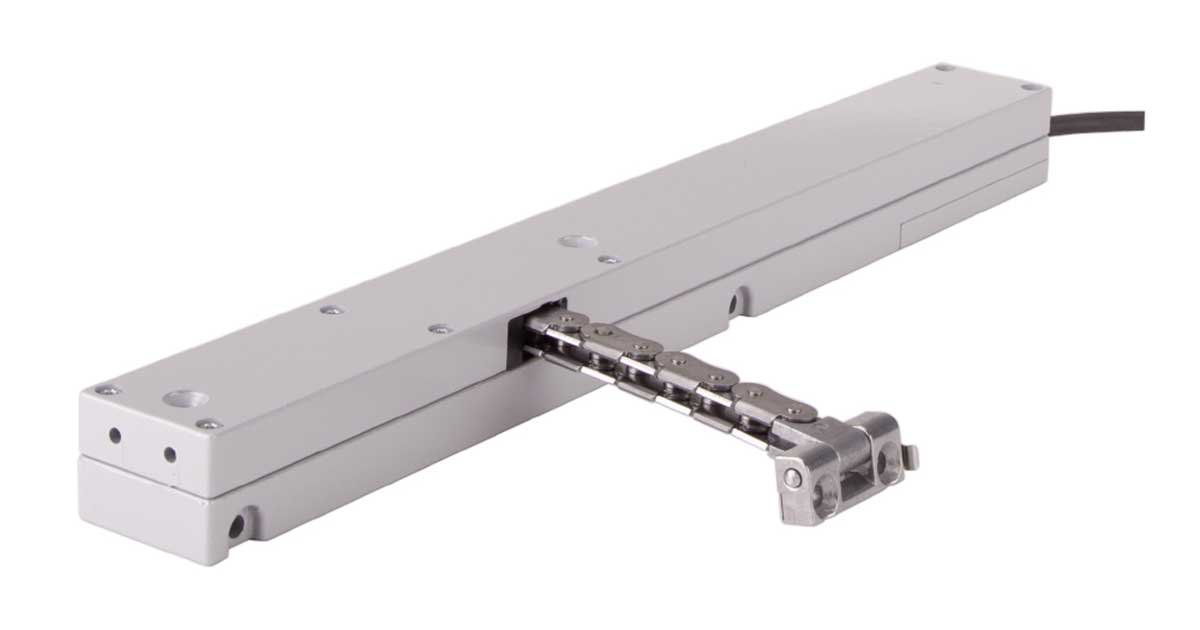

Structure of chain drives

A motor is installed in an aluminum profile or between two plastic half-shells, which drives a chain pinion via a reduction (gear). When the motor and thus the chain pinion rotate, the chain is pushed out or pulled in at the side of the profile. The drive either moves to the respective end position (retracted, extended) or stops at the respective intermediate position when the supply voltage is removed.

If the drive is overloaded, for example because it does not have enough power, two cases can occur:

- The drive has an electronic load cut-off. In this case, the drive simply stops. From the drive's point of view, this is a "normal" mode of operation - the drive suffers no damage as a result.

- The drive switches off in the end positions via reed contact or microswitch. In this case, the motor will burn out after a short time if it is blocked, because an extremely high current flows and it overheats.

The design of the chain is such that it can only be folded to one side. Our pictures show the straight chain, as well as the chain bent in the only possible direction.

The drive is installed so that the chain has an angle of 90° to the drive housing when it is extended. This means that it is under tension and almost as firm under load as, for example, a metal push rod.

Installation

Due to its design, every chain has tolerances because of the movable chain links. Therefore, such a chain can also be bent slightly to the other side.

The radius that can be achieved with this is about 100cm. If we assume a standard installation (facade window, tilt sash inwards), the drive can be fixed at a sash height of 100cm (drive is fixed to the window frame). If the window is opened and the chain moves out, it "bends" with a radius of 100cm and is thus within the tolerance range. If the sash is smaller (i.e. the window is not very high), the drive must be fixed with swivel brackets. These ensure that the entire drive moves a little with it and the chain is not loaded laterally. However, swivel brackets require a little more space on the window frame.

Pros & Cons

For chain drives speaks the fact that they do not stand in the room, because they are mounted transversely. This makes them relatively inconspicuous, and injuries from bumping are also avoided.

Chain drives are usually poorly protected against water ingress in the area of the chain outlet. So you have to take care during installation that no water can run along the chain (rain guard...). Normally this plays a role with skylights or special constructions, here the chain exit is in the direction of the ceiling, the chain gets wet in case of rain and transports the water exactly into the drive.

Large lifting forces are also poorly possible with these drives. 600N lifting force is within the range of feasibility, higher lifting forces are possible, but the drives then also become significantly more expensive (ask us about this). Of course, the question arises whether forces above 600N are necessary at all - but more about that elsewhere.